The packaging of granular glue or hot melt adhesives and chemical products is one of the sectors in which we have the most experience.

Over the years, we have carried out several projects for the construction of complete plants or additions to existing systems.

In the following case history, we will analyze:

- The hot melt adhesive market

- Specific features of the project

- Machinery involved

- Why choose MF TECNO

- Video testimonial

Hot melt adhesives market

According to Future Market Insight, the hot melt adhesives market will experience significant growth in the coming years. It will grow at a CAGR of 4.3%, reaching $9.8 billion by the end of 2030.

The sectors most involved are packaging, automotive, woodworking, and paper bonding.

Specificity of the project

The construction of this plant is the result of collaboration with one of the most important manufacturers in the sector in Northern Italy.

Unicol, a company active in the sector since the 1980s, was looking for a company with proven experience in the field of granular glue packaging.

In other words, a company that had already collaborated with companies in the sector.

Another key element, given the specificity of the project, was the ability to correctly manage the product flow.

The project involves combining Mial and MF Tecno technology. The product goes from an initial transport and mixing phase to the next packaging and palletizing phase.

A complete system that guarantees traceability at every stage, in line with Industry 4.0 and capable of combining fluidity, speed, and efficiency.

The transport and mixing phase consists of two AISI 304 stainless steel propellers, pneumatic transport, and three vertical mixers, each with a capacity of 3,000 liters.

The next phase of packaging involves the production of 20-25 kg bags of granules. This solution has a medium-low productivity of 200-300 bags/hour in pillow bags with side gussets.

The machinery involved

The wide range of machinery available allowed us to meet the specific needs of the customer. The choice fell on:

- Pneumatic conveyor and vertical mixer

- MF 58 packaging machine

- Smart palletizer

- Semi-automatic pallet wrapper

Pneumatic conveyor and vertical mixer

The pneumatic conveyors and vertical mixers, upstream of the bagging phase, meet the need to ensure the continuity of production batches.

Each pneumatic conveyor is connected to a 3000-liter vertical mixer, allowing for separate batch management.

The MIAL vertical mixer, made of AISI 304 stainless steel, prevents clumping and ensures homogeneous mixing of the product.

The particular precision in the machining and the resulting proximity of the blades to the walls of the tank improve the homogeneity of the mixed product.

It is capable of mixing large quantities of product and is designed to ensure easy cleaning when changing production.

This prevents the accumulation of residual material.

MF 58 Vertical Packaging Machine

This vertical packaging machine has been specifically designed for packaging products with good flowability and particle size.

The most suitable products are: soil, seeds, feed, and plastic granules.

Ideal for medium to large production runs. 20-25 kg bags.

Starting from a flat film reel, the bag is formed around the tube and heat-sealed vertically and horizontally.

Vertical packaging machines can produce pillow bags or gusseted bags using special devices.

The bags produced in this case are pillow bags with side gussets with three seals, two horizontal and one vertical. If necessary, our VFFS machines can also produce bags with four seals.

It is equipped with an inspection platform for the scale. The scale chosen is a net weight electronic scale with gravity feed. Particularly suitable for products with excellent flowability.

Image of the MF 58 packaging machine

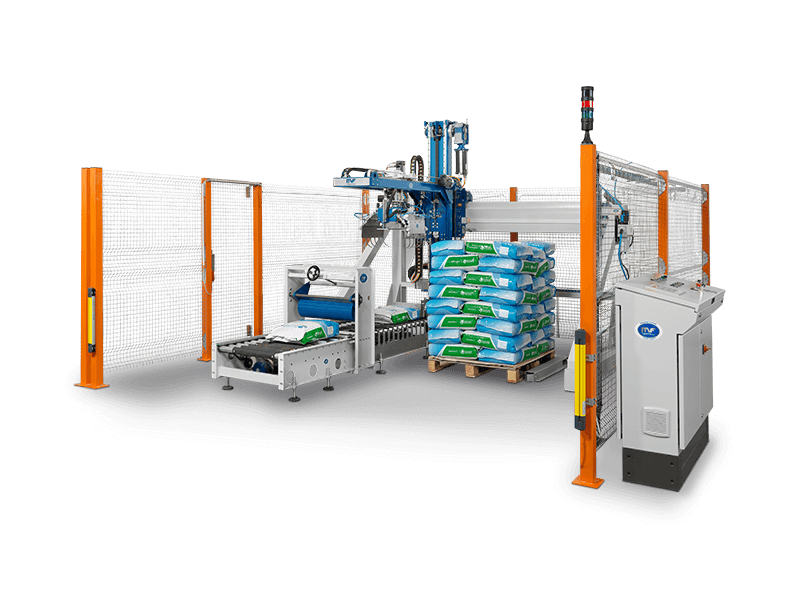

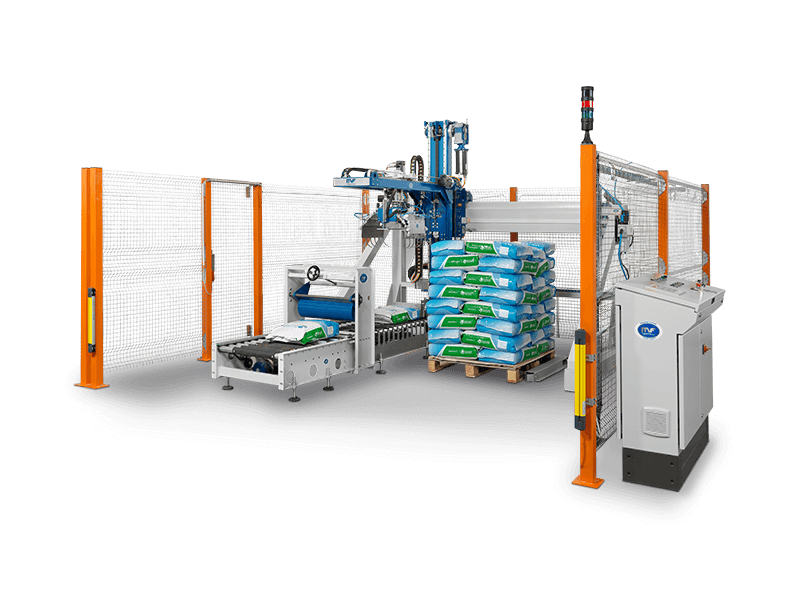

Palletizing robot for granular products

In line with the customer's requirements, the choice fell on the PCA Smart Cartesian palletizer. One of our top-of-the-range solutions.

It is equipped with roller conveyors, chain conveyors, and an automatic pallet magazine for the automatic feeding of empty pallets and the automatic evacuation of full pallets.

Designed for medium production rates of up to 500 cycles/hour, it is capable of handling loads of up to 50 kg.

Its compactness and small size make it an ideal solution when there is a need to work in confined spaces. It has small dimensions and a limited footprint. Just under 3 meters long and a pallet height of 1,800 mm (including the pallet).

The operator has complete control of the palletizing pattern thanks to the integrated PLC system equipped with a touch screen.

Its modular structure allows for multiple assembly combinations and high adaptability to different work environments and existing systems.

It is also designed for use with different gripping solutions, which can be customized according to requirements.

The entire machine is enclosed within safety guards.

Image of the MF PCA SMART Cartesian palletizer

Semi-automatic pallet wrapper

To complete the palletizing process, the wrapper automatically starts the wrapping process. In fact, the wrapping and palletizing cycles are synchronized with each other.

The MF SPW 20 semi-automatic rotating platform wrapper is a flexible and easy-to-use solution. It can be made entirely of stainless steel and is equipped with PLC control.

The platform rotation speed is 10 rpm.

Why choose MF TECNO

We specialize in the manufacture of complete packaging systems.

Our extensive range of machinery allows us to carry out projects involving transport systems and primary and secondary packaging.

Choosing us means relying on a solid company whose machinery is entirely manufactured in-house. It means relying on a single point of contact who is entirely responsible for the entire project, thus avoiding lengthy conflicts of responsibility.

We guarantee fast delivery times and efficient customer service.

Image of the test run

FREE QUOTE

FREE QUOTE  Machinery

Machinery Open Mouth Bagging machines

Open Mouth Bagging machines Vertical packaging machines

Vertical packaging machines FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information