MF TECNO USA Machinery  FREE QUOTE

FREE QUOTE

-

Machinery

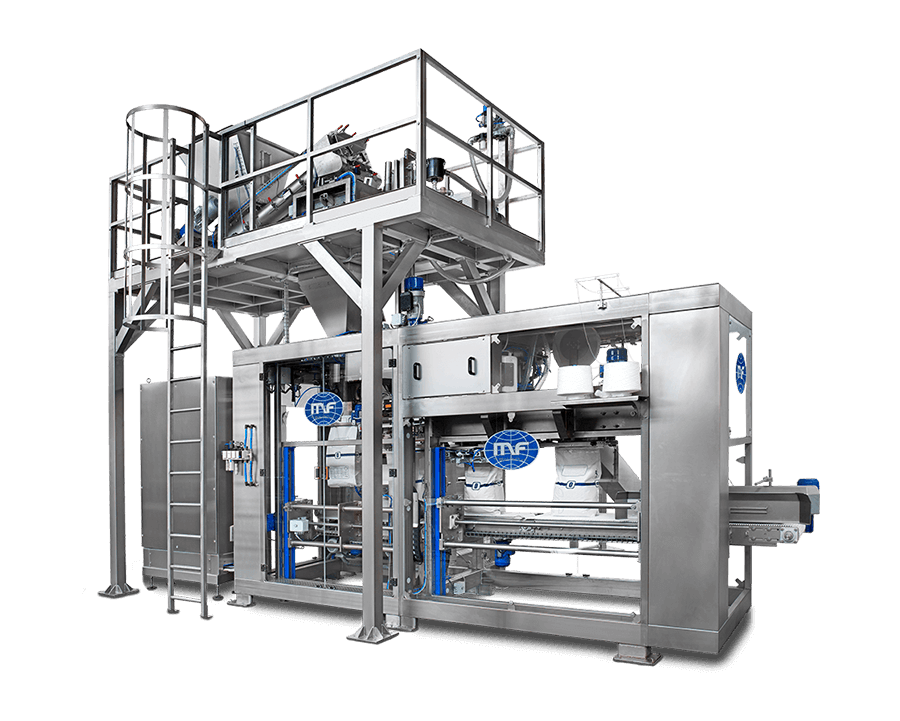

Machinery - Open Mouth Bagging machines

-

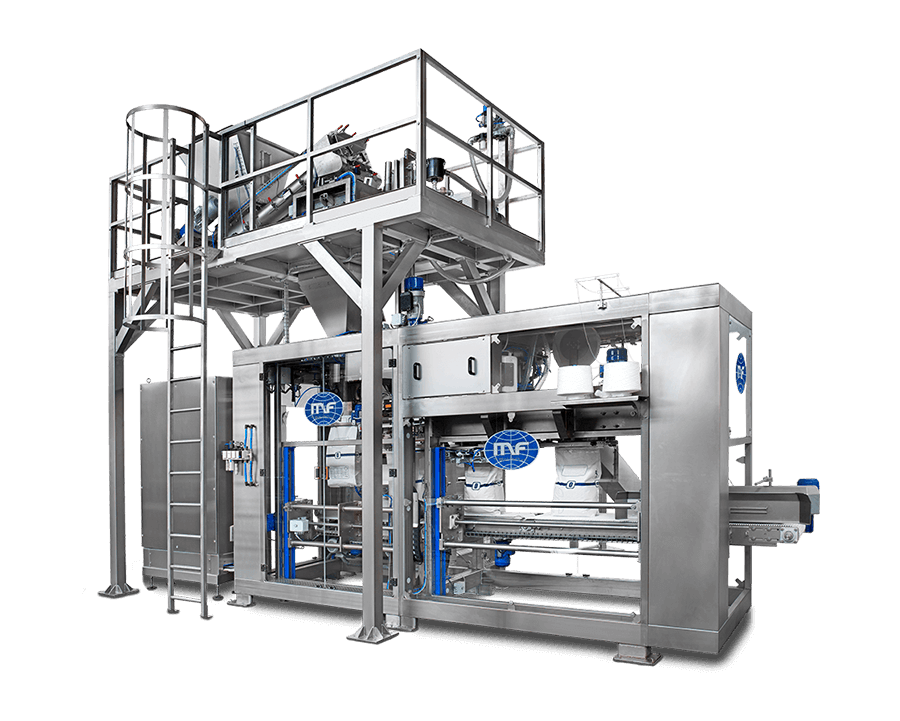

Open Mouth Bagging machines

Open Mouth Bagging machines - SMALL BAGS

- MEDIUM - LARGE FORMATS

- SEMIAUTOMATIC

-

- FFS Tubular Machine

- Vertical packaging machines

-

Vertical packaging machines

Vertical packaging machines - SMALL BAGS

- MEDIUM - LARGE FORMATS

-

- Flow Pack

- Palletizers

- Pallet wrappers

- Case Packers

- Shrink wrappers

- Pick & Place

- Big-bag

- Product loading and transport

- Accessories and pallet handling

- SEE ALL MACHINES

FREE QUOTE

FREE QUOTE

MF TECNO USA Machinery Your products Packaging Lines Customer Support

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information

Discover more

Discover more