The food sector is probably the most demanding when it comes to the quality and precision of packaging machinery. The parts in contact with food are made of stainless steel. In addition to the aesthetic aspect of the bag, the packaged quantity should be as precise as possible to avoid waste.

With this in mind, we designed a plant capable of producing small size bags that could satisfy these needs.

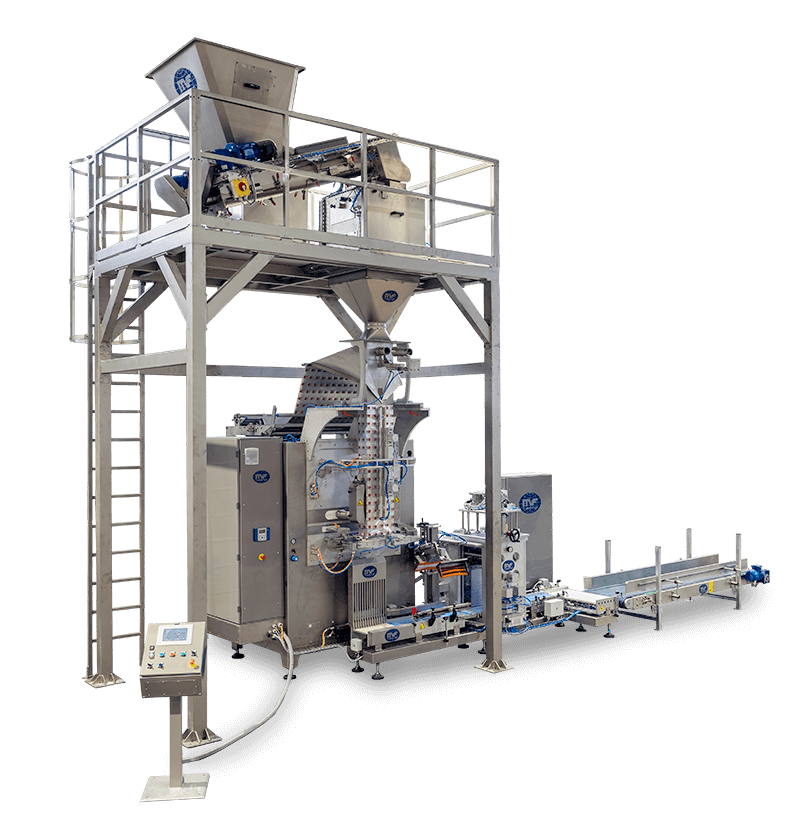

This system has been designed for the packaging of beans, rice, legumes in general, short pasta and the like in pillow bags or double square bottom.

This food product packaging line consists of various machines.

Initially, the product is loaded through a tilting bucket elevator, fed by a vibrating channel.

The weighing takes place using a multi-head weigher that feeds the vertical carousel packaging machine MF 52 DFQ. The bags are then positioned on the boxes by a pick & place system. The boxes are formed and closed by the automatic case packer, which produces American-type boxes.

As anticipated, the carousel packaging machine is initially fed by a vibrating channel. This system is ideal for granular products, with variable flowability and fragile bulk products.

The pendulum bucket elevator represents the best compromise for the transport of delicate goods at height, guaranteeing their integrity.

Its modular structure allows it to be used for the most varied needs, allowing it to be installed in confined spaces.

The possibility of having several variable loading and unloading points guarantees maximum flexibility of use.

The electronic multihead weighers allow to carrying out precise weighing of a wide variety of food and non-food products, with high speeds. This weigher, available in various models, can reach up to 120 weights per minute, based on the size and the degree of flowability of the packages.

The functioning of the multihead weighing system is based on advanced software that allows reaching the desired weight by exploiting the average of the cells.

The weigher is available with 10 or 20 heads with baskets from 1.5 to 5.0 litres. It is designed to weigh products of various sizes with different granulometry, with high precision and without sacrificing the weighing speed.

The MF 52 automatic packaging machine is designed to pack rice, dried legumes and any food product in small formats.

Another strong point of this food packaging system is the ability to manage both double square bottom bags and pillow bags. The operation speed reaches up to 50 BPM.

The system receives the filled and partially closed bag from the vertical packaging machine and a series of devices allows to remove excess air. Once the package is closed, the upper flap is folded back on itself and finally fixed, thus creating the double square bottom.

The modularity of the device allows the combination with open and close adhesive applicators, markers, printers and labellers.

The carousel can be made according to the type of product to be packaged and the format to be made.

The pick and place system, using an anthropomorphic robot, allows you to place a given number of bags in the boxes. In this case, the management of the two types of bags requires a different gripper and loading system.

This food packaging solution ends with the boxing machine with the automatic warehouse. This machine automatically forms and closes the cardboard boxes that contain the previously formed bags.

The typology created is the American box. It can handle up to 20 cartons per minute.

Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more