The Cartesian Palletizer is the ideal solution for optimizing production processes and the secondary packaging phase.

Integrated with the packaging line, it can be the ideal choice for a complete turnkey plant.

It simplifies the handling and transportation of goods, supporting and increasing business performance. In fact, it enables the automated and smooth management of the entire production flow.

In fact, it takes care of the lifting, moving and stacking phases of a large quantity of products following a preset work scheme.

This, established at the design stage, follows the specific needs of the warehouse and production cycle.

The touch screen display allows the operator to easily adjust operating parameters and independently modify the palletizing scheme.

A highly flexible and high-performance solution, it enables the autonomous handling of an almost infinite variety of packages such as boxes, bags, trays, drums and cans.

It guarantees precision, safety and high productivity on the one hand, and on the other eliminates the need to rely on labor to perform manual, repetitive and wearing tasks.

In the following article we will discuss:

Operation of the Cartesian robot palletizer is simple.

The rigid and compact structure of the machinery ensures the stability necessary for proper operation of the mechanical arm.

The vertical, horizontal and diagonal movement of this arm, along the 4 Cartesian axes and around its own axis, with 360° rotation, allows lifting and transporting of goods from a platform to the pallet. The latter movement then ensures flexibility of use and the creation of an extremely compact and stable pallet.

The presence of a gripper at the top of the arm, which can be adapted to different palletizing needs, takes care of the actual handling of the product.

In fact, depending on the characteristics of the product and the type of package, different types of gripper heads can be opted for. Those with forks, suction cups or special grippers for boxes.

This solution is a recommended choice when:

MF TECNO Cartesian Palletizers

We at MF Tecno have a wide range of Cartesian palletizers and anthropomorphic robots.

Different solutions in line with different customer and palletizing needs.

Single installations or integrative solutions of complete packaging plants.

Below we will analyze in detail:

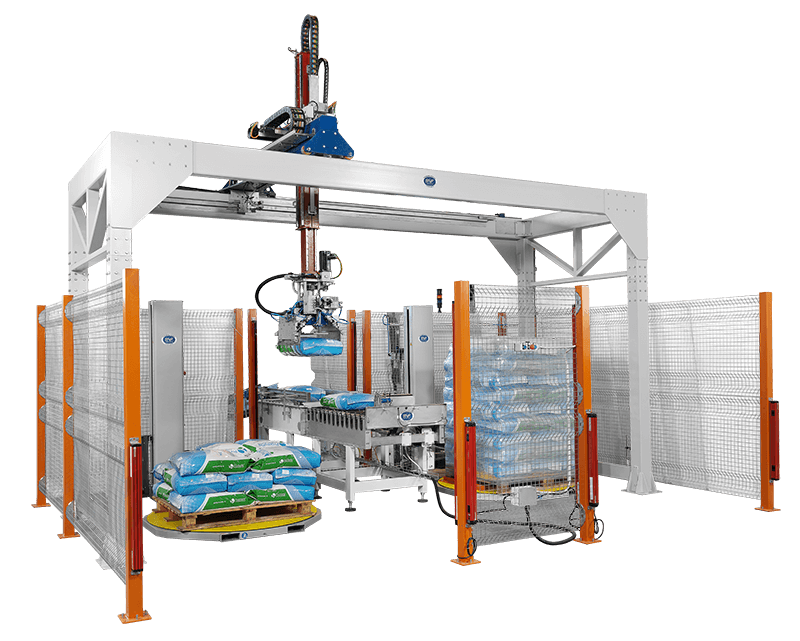

The PCA Smart Cartesian palletizer is the ideal choice for processing medium productions. Suitable for processing loads up to 50 kg and productions reaching 500 cycles/hour.

A high-performance and reliable solution, it is perfect for product handling in confined spaces and prohibitive environments.

In fact, the extremely compact and stable structure is just under 3 meters.

The pallet, on the other hand, reaches maximum dimensions of 1800 mm (including pallet). It remains possible to achieve different pallet sizes in line with specific customer requirements and needs.

On the other hand, the modular design ensures different mounting combinations and allows it to adapt to different working environments and pre-existing packaging lines.

Depending then on the customer's needs we distinguish:

The operator, thanks to the PLC system equipped with a touch screen, has complete control of the palletizing scheme. This represents an easy and intuitive solution that allows the operator to independently modify or create a new palletizing scheme.

The machinery is prepared for the use of different gripping solutions with the possible inclusion of numerous optional extras, depending on the customer's needs.

In order to protect the safety of the operator there are numerous safety devices.

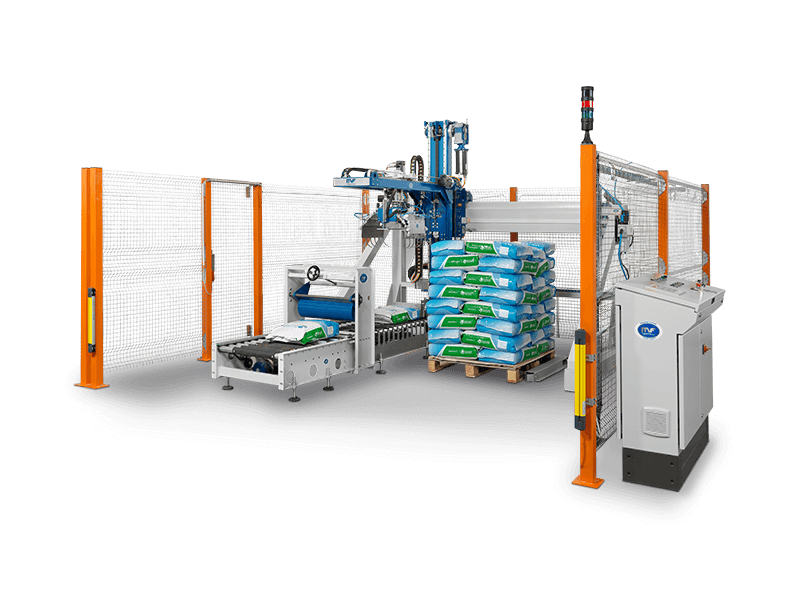

The MF PCA SMART PRO Cartesian palletizer, provides high throughputs of up to 800 cycles/hour for loads up to 50 kg.

The palletizer ensures versatility and convenience, customizable according to customer needs and project specifications.

The PRO version differed from the standard version in 3 main features:

The standard height is just under 3 meters, while the finished pallet has a maximum height of 1800 mm (including pallet).

Suitable for installation even in tight spaces, it fits any pre-existing end-of-line.

It allows the storage, handling and transport of many types of products: bags, boxes, cases and bundles.

The machinery combines reliability, excellent value for money, compactness and production speed.

Like the PCA Smart palletizer, Smart PRO also has a basic and an automatic version.

Depending on the project specifications, different gripping solutions are possible, which can be supplemented with various options.

These ensure the palletizing of boxes, bundles and bags.

The heads rotate around their own vertical axis so that the sack is deposited according to the pattern provided by the work program.

In order to protect the safety of the worker, we guarantee all necessary safety measures.

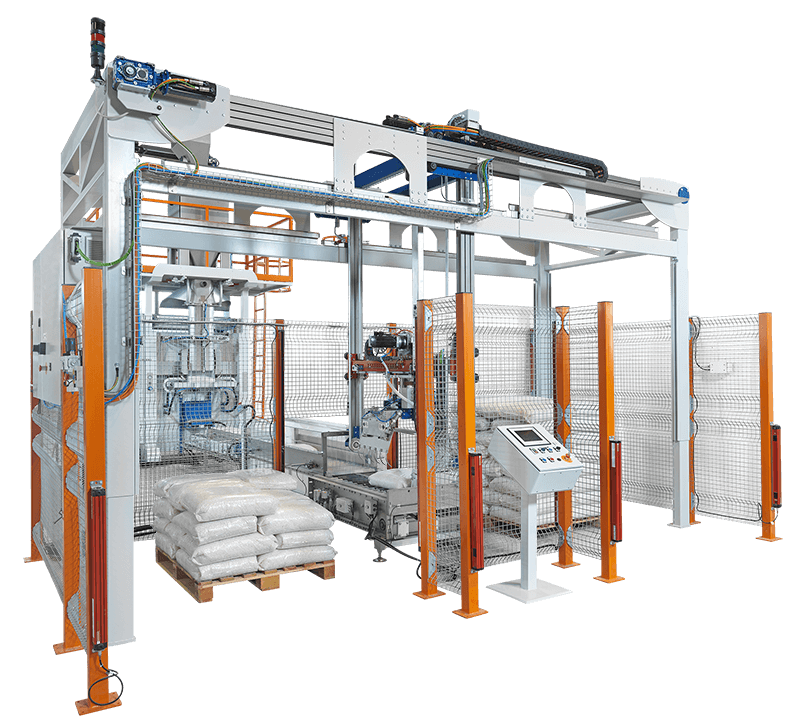

The MF PCA 700 Twin palletizer, on the other hand, represents the perfect solution for anyone looking for high productivity and working autonomy.

In fact, it guarantees the handling of medium/high productions, up to 700 cycles/hour while the PCA 400 version is instead prepared medium/low productions.

The Twin version is characterized, compared to the traditional version, by the double palletizing station. In fact, it enables seamless working.

Once the pallet is finished at the first station, machining begins immediately at the second palletizing station.

This avoids stopping the production cycle resulting in gains in overall productivity.

The modular design allows multiple mounting combinations and adaptation to different working environments and pre-existing systems.

Equipped with Brushless motors, safety devices and safety guards, it is suitable for the use of different gripper modules.

We have decades of experience in the implementation of palletizing systems. Both single projects and complete packaging systems and turnkey solutions.

Relying on us means choosing a solid, quality-conscious company that manufactures every component of our machinery fleet in-house.

In-house production enables us to guarantee fast delivery times and reliable and timely dedicated customer service.

Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more