The Cartesian palletiser is the perfect solution for production process optimisation and secondary packaging.

Integrated with the packaging line, it can be the ideal choice for a complete turnkey system.

It facilitates the handling and transport of goods, supporting and increasing company performance. In fact, it provides automated and smooth management of the entire production flow.

In effect, it handles the lifting, moving and stacking of a large quantity of products according to a predefined work plan.

This, established during the design phase, follows the specific needs of the warehouse and the production cycle.

The touch screen display allows the operator to easily adjust the operating parameters and modify the palletising scheme independently.

A highly versatile and high-performance solution, it allows the autonomous handling of an almost infinite variety of packages such as boxes, bags, trays, drums and cans.

It guarantees precision, safety and high productivity on the one hand, and on the other hand removes the need to entrust manual, repetitive and time-consuming tasks to labour.

In the following article we will discuss:

- Cartesian palletizer operation

- MF TECNO Cartesian Palletizer

- Why Choose MF TECNO Cartesian Palletizers

Cartesian palletizer operation

The functioning of the Cartesian palletising robot is simple.

The rigid and compact structure of the machine ensures the stability necessary for the proper functioning of the mechanical arm.

The vertical, horizontal and diagonal movement of this arm, along the 4 Cartesian axes and around its own axis, with 360° rotation, enables goods to be lifted and transported from platform to pallet. This latter movement then ensures ease of use and the creation of an extremely compact and stable pallet.

The presence of a gripper in the upper part of the arm, which can be adapted to different palletising requirements, takes care of the actual handling of the product.

In fact, depending on the product's characteristics and the type of packaging, one can opt for different types of gripping heads. Those with forks, suction cups or special grippers for boxes.

This solution is a recommended choice when:

- There is a limited amount of space available

- A stable and precise load must be achieved.

- Flexibility in use and the capacity to handle different types of bags is required.

MF TECNO Cartesian Palletizers

At MF Tecno we have a wide range of Cartesian palletisers and anthropomorphic robots.

Different solutions in line with different customer and palletising requirements.

Single installations or supplementary solutions for complete packaging plants.

Below we will analyze in detail:

- Cartesian palletiser for medium production

- Cartesian palletiser for high production

- Cartesian double-station palletiser

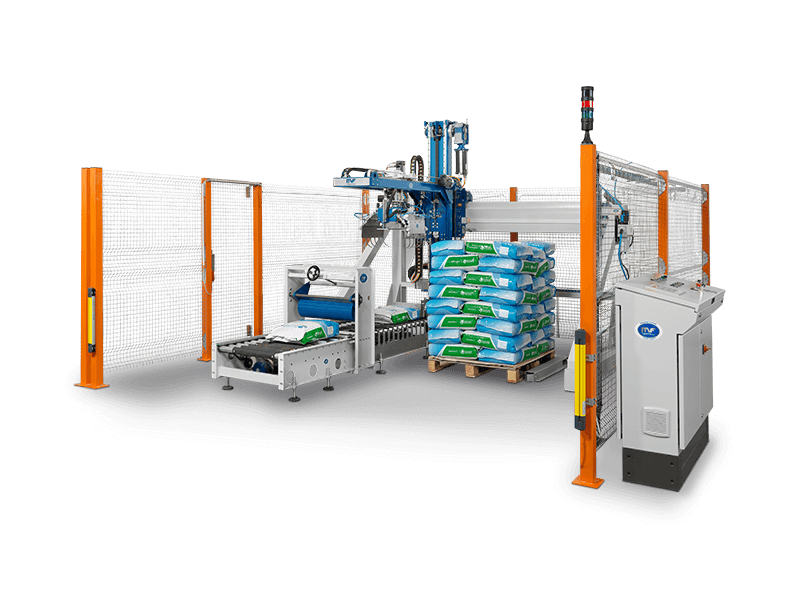

Cartesian palletizer for medium production

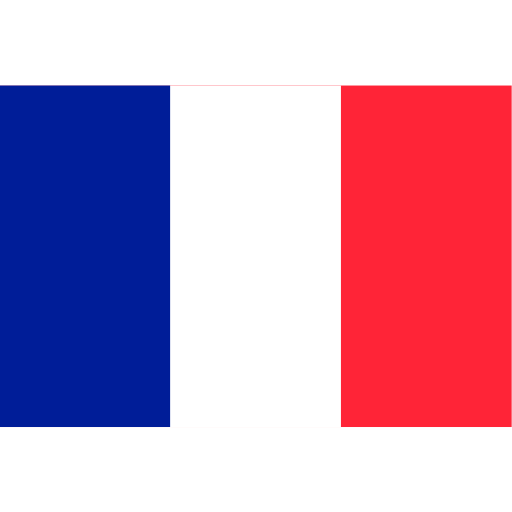

The PCA Smart Cartesian palletiser is the perfect choice for processing medium production runs. It is suitable for processing loads of up to 50 kg and throughputs of up to 500 cycles per hour.

A high-performance and reliable solution, it is perfect for handling products in confined spaces and prohibitive environments.

In fact, the extremely compact and stable structure is just under 3 metres.

The maximum pallet size is 1800 mm (including pallet). However, it is possible to obtain different pallet sizes in line with specific customer requirements and needs.

On the other hand, the modular design guarantees different assembly combinations and allows adaptation to different working environments and existing packaging lines.

Depending then on the customer's needs we distinguish:

- Basic version, in which the material is deposited on pallets on the ground or on semi-automatic wrappers.

- Automated version, in which the palletising robot is integrated with an automated pallet magazine.

The operator, thanks to the PLC system equipped with a touch screen, has complete control of the palletising scheme. This is an easy and intuitive solution that allows the operator to independently modify or create a new palletising scheme.

The machine is prepared for the use of different gripper solutions with the possibility of including numerous optional extras, depending on the customer's needs.

Numerous safety devices are in place to protect the operator's safety.

Cartesian palletizer for high production

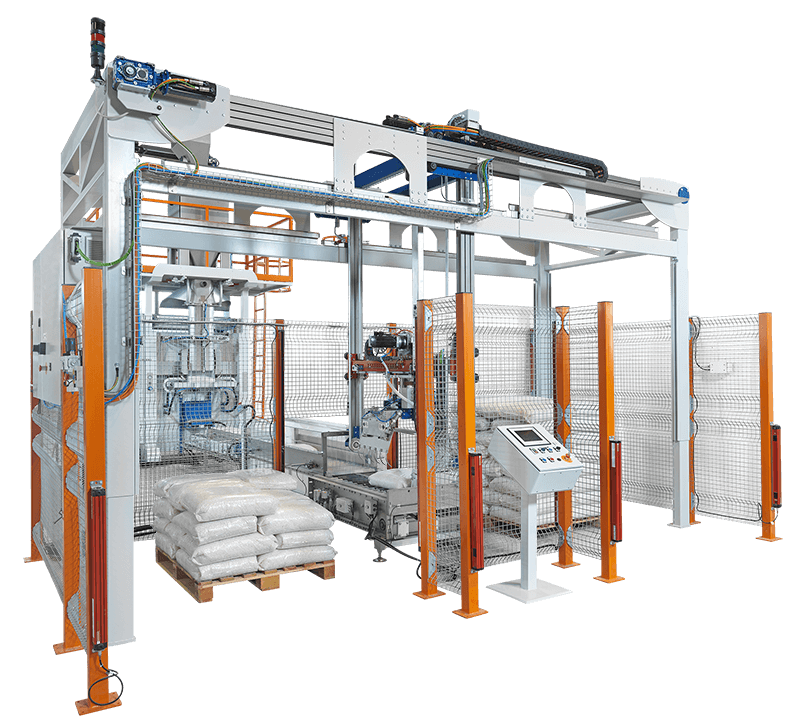

The MF PCA SMART PRO Cartesian palletiser offers high productivity, up to 800 cycles/hour for loads up to 50 kg.

The palletiser provides flexibility and convenience, customisable to suit customer requirements and project specifications.

The PRO version differed from the standard version for 3 main features:

- Aluminium construction makes the machine lighter and faster.

- A more advanced work programme ensures optimised productivity.

- Machine engines are more powerful.

The standard height is just under 3 metres, while the finished pallet has a maximum height of 1800 mm (including pallet).

Suitable for installation even in confined spaces, it adapts to any existing end-of-line.

It allows the storage, handling and transport of many types of products: bags, boxes, crates and bundles.

The machine combines dependability, excellent value for money, compactness and production speed.

Like the PCA Smart palletiser, Smart PRO also has a basic and an automatic version.

Depending on the project specifications, different gripping solutions are available, which can be supplemented with various options.

They ensure the palletisation of boxes, bundles and sacks.

The heads rotate around their own vertical axis so that the sack is deposited in accordance with the work schedule.

To protect the safety of the worker, we guarantee all necessary safety precautions.

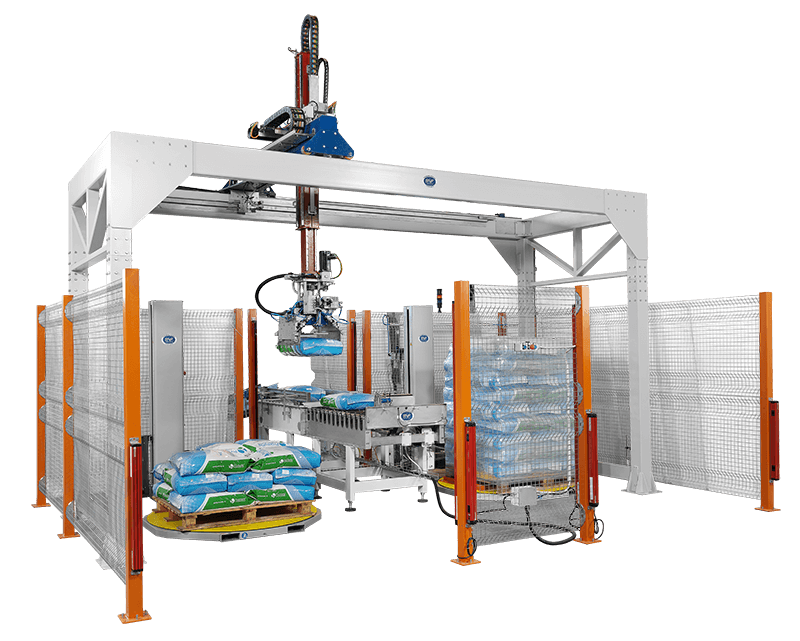

Cartesian double-station palletizer

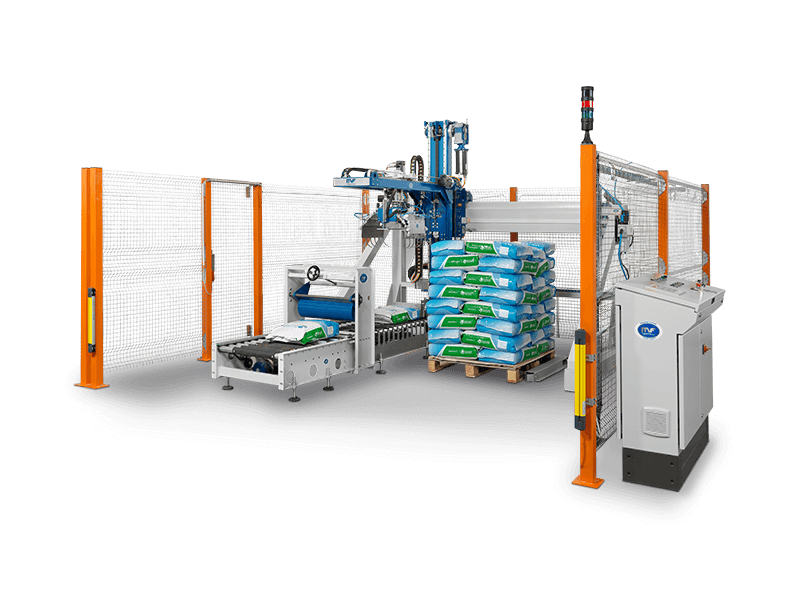

The MF PCA 700 Twin palletiser, on the other hand, is the perfect solution for those seeking high productivity and autonomy.

In fact, it guarantees the handling of medium-high production, up to 700 cycles/hour, while the PCA 400 version is designed for medium-low production.

The Twin version is characterised, compared to the traditional version, by the double palletising station. In fact, it allows seamless working.

Once the pallet is finished in the first station, machining starts immediately in the second palletising station.

This avoids interrupting the production cycle, thus increasing productivity as a result.

The modular design allows multiple mounting combinations and adaptation to different working environments and existing systems.

Equipped with brushless motors, safety devices and guards, it is suitable for the use of various gripper units.

Why Choose MF TECNO Cartesian Palletizers

We have decades of experience in the implementation of palletising systems. Both individual projects and complete packaging systems and turnkey solutions.

Relying on us means choosing a solid, quality-conscious company that manufactures every component of its machinery in-house.

In-house production allows us to guarantee fast delivery times and reliable, timely customer service.

FREE QUOTE

FREE QUOTE  Machinery

Machinery Open Mouth Bagging machines

Open Mouth Bagging machines Vertical packaging machines - VFFS

Vertical packaging machines - VFFS FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information