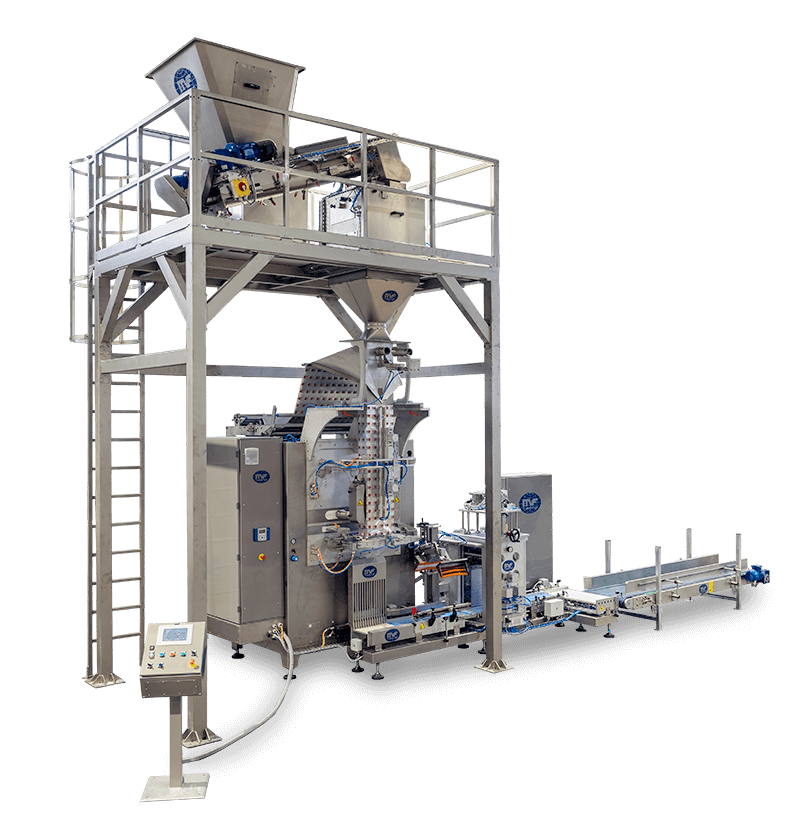

Tubular chain conveyors are used to transport large quantities of materials easily and safely.

TUBULAR CHAIN CONVEYOR

What is the Tube Chain Conveyor?

The tubular chain conveyor can transport large quantities of material over long distances, safely and efficiently.

It is suitable for conveying all sorts of granular, powdery, friable, and delicate products such as powders, chemicals, plastic granules, thermoplastic elastomers Tpe, pet food, agri-food products, animal feed, pellets, dried fruit, and candies.

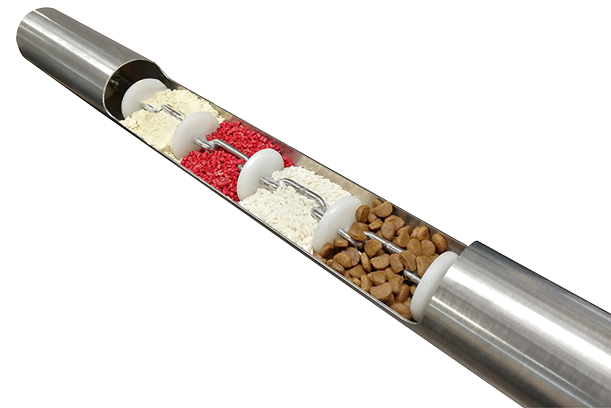

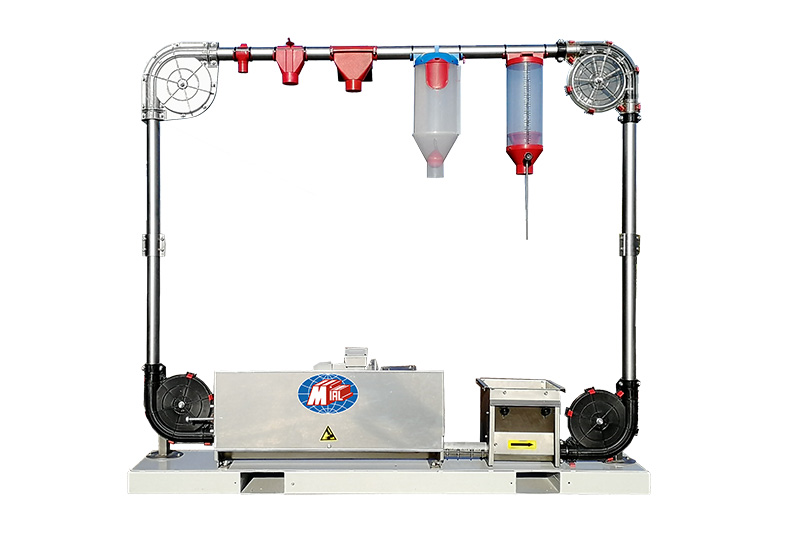

How does a Tubular Conveyor work?

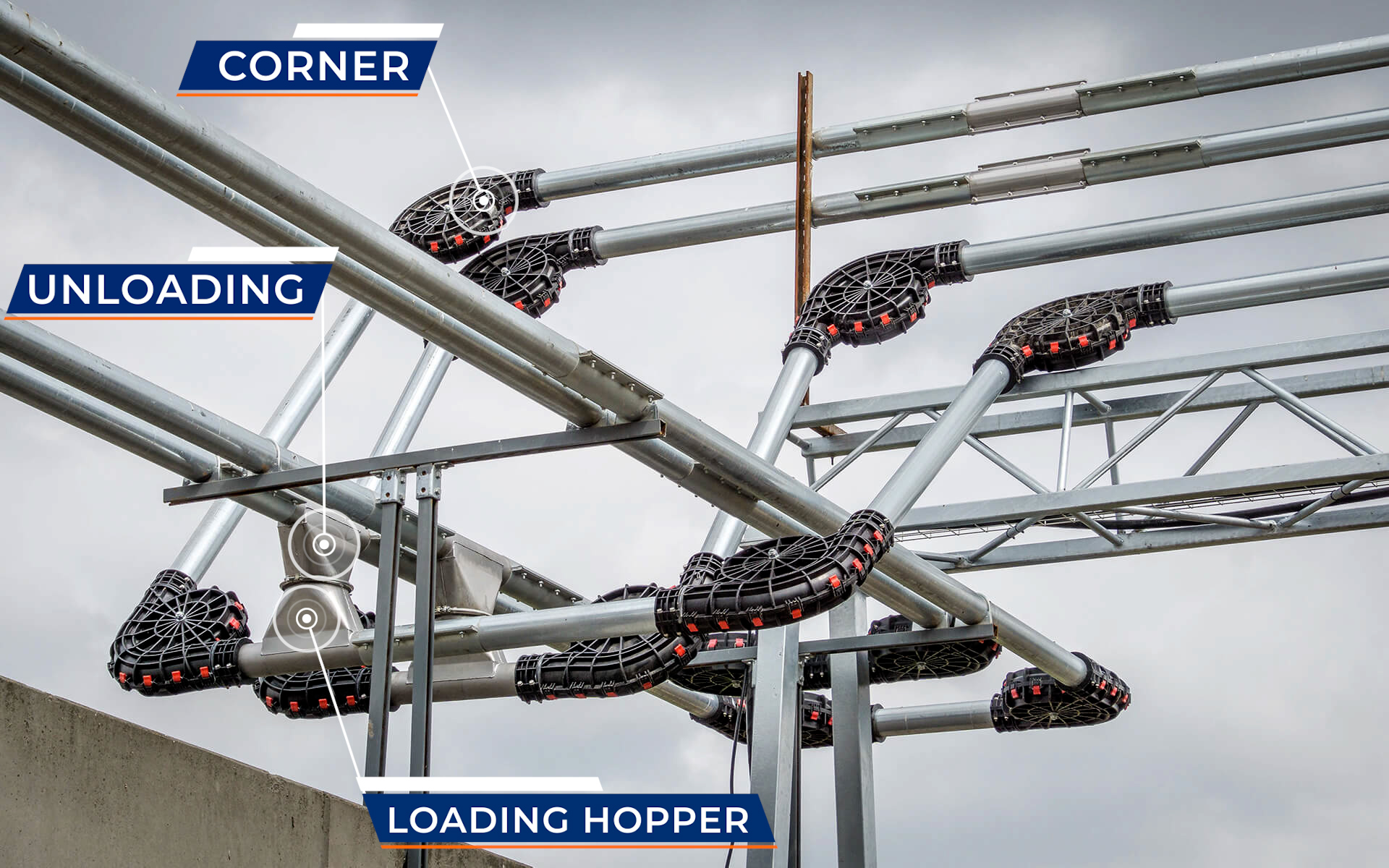

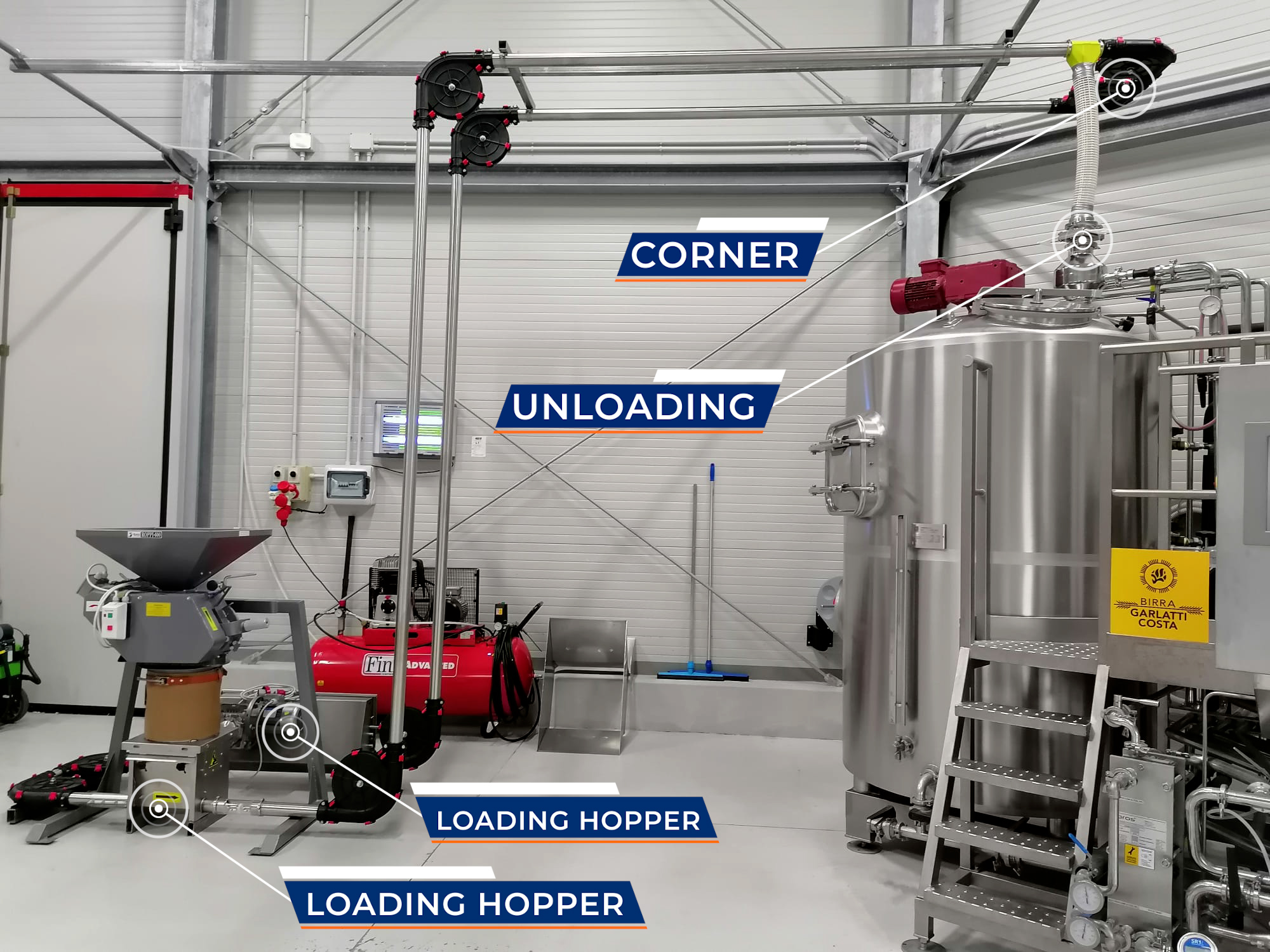

The conveying system consists of tubes, curves/corners, and loading and unloading hoppers.

These are our solution:

Ideal for Malt, Cereals, Animal feed, Plastic materials

Ideal for Seeds, Pet food, Cereals, Granular products

Ideal for Coffee beans, Bulk ingredients, Grains, Wooden pellets

.png)

All the reasons to choose Tubular Chain Conveyor:

Plant section installed in China

Plant section installed at Garlatti Beer

Read the article below and find out about one of the largest chain conveying systems designed and installed by MIAL.

Request information

Request information

There are many reasons to choose our products

Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more  Discover more

Discover more Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more