Automatic vertical packaging machines, often abbreviated to VFFS, are used for packing a wide range of bulk products.

Among the most common are pet food, frozen food, dried fruits, sand and aggregates, pellets, compost, and plastic granules.

Vertical form fill sealers (VFFS) are extremely simple and effective.

They are a quick and efficient way to package a bulk product in hermetically sealed, standardised packages.

In the following article we will analyse:

The packaging process is particularly effecient due to the continuous formation of the bags.

In fact, the creation of the bag takes place as soon as the previous unit has been sealed.

The process of creating the single-dose pack starts from the flat film of the reel. This, once filled with product, is hermetically sealed using special sealing bars.

The eventual use of aluminized laminated films helps preserve the freshness and fragrance of products.

The opportunity to use compostable or recyclable films is an excellent "green" solution.

Correct and constant dosing is ensured by special multi-head weighers and automatic weight systems.

In fact, rather than having to buy several bags of different sizes, a single roll of film can be used to make several packages of different sizes.

In this way, there is no need to accumulate unnecessary quantities of packs. Furthermore, the possibility of using thinner film reduces material costs.

VFFS have many fields of application and can therefore be used for different types of products. As much for solid and granular ones as for powdery ones.

Among the most common are those related to:

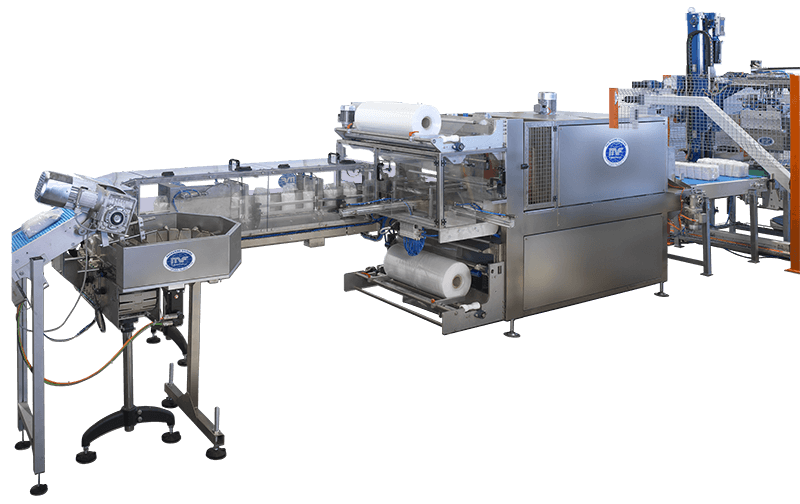

Our company specialises and has considerable experience in the design and manufacture of vertical packaging machines.

Thanks to our numerous installations, we have developed a wide range of machines to meet different customer requirements.

Individual installations, turnkey solutions or additions to existing systems.

Various designs and types of processed bags. Pillow bags, with side gussets, square bottom, double square bottom, three or four seal or valve bags.

We distinguish in our fleet:

VFFS for small formats

VFFS for medium formats

VFFS for big formats

VFFS for Vacuum

Space-saving, easy-to-use and cost-effective vertical packaging machine

It is suitable for packaging products in small quantities (50 g to 1 kg).

It can produce both pillow and square bottom bags, with minimum dimensions of 65 x 60 mm and maximum dimensions of 180 x 270 mm.

Vertical packaging machine with continuous technology (hence the name "Speedy").

It is a high-performance machine suitable for confined spaces.

Just like the MF 50, it is adapted for packaging products in small dimentions (maximum 1 kg), but with a higher production rate (100 to 110 bags/min.).

Characterised by high production speed, ease of operation and maintenance.

It produces packages ranging from a minimum of 40 x 50 mm to a maximum of 190 x 400 mm.

Vertical packaging machine suitable for packaging products in medium-sized packs (1 to 5 kg).

Due to brushless motors, it achieves 50 bags per minute.

These are of different shapes and types and have a minimum size of 20 x 100 mm and a maximum size of 330 x 400 mm.

A particularly versatile continuous motion vertical packaging machine model.

It is distinguished by its high packaging speed. In fact, it can reach 80 bags per minute.

These have minimum dimensions of 120 x 100 mm and a maximum dimensions of 330 x 400 mm.

Vertical packaging machine with carousel system for medium/high output and medium formats (1-5 kg).

Designed specifically for the production of double square bottom bags.

The process starts with bag formation and removal of excess air. Finally, it proceeds to closing the bag by folding and securing the top flap on itself.

Vertical packaging machine for formats from 5 to 30 kg. Easy to use and extremely versatile.

It has a production capacity of 1,200 bags per hour.

Particularly used for products such as: animal feed, cereals, flour, sand, aggregates, pellets.

Allows bags with minimum dimensions of 230 x 300 mm and maximum dimensions of 470 x 680 mm.

Allows the packaging of products characterised by good flowability and grain size. Suitable for packaging large sizes. Up to 30 kg.

Featuring a production capacity of 1200 bags per hour.

Can handle different types of bags: pillow, side-gusset, four-seals, square-bottom.

The presence of the touch screen panel and alphanumeric display also offers easy management and modification of the packaging scheme.

The use of Brushless motor also guarantees maximum efficiency and reduced maintenance.

Vertical packaging machine suited for handle large formats from 5 up to 50 kg.

It achieves production capacities of up to 1,200 bags per hour.

Especially used for products such as pet food, feed, seeds, soil, plastic granules.

It can produce with minimum dimensions of 350 x 600 mm and maximum dimensions of 630 x 1180 mm.

Solution suitable for medium-sized vacuum packaging (1 to 5 kg).

A choice that results in a pack with a compact and perfectly square configuration. Useful to preserving fragrance and storage value.

Can make bags as small as 120 x 100 mm and as large as 330 x 400 mm.

Vertical packaging machine for large formats (5 to 30 kg), with vacuum packaging.

It is equipped with a single or double vacuum bell configuration, which influences the productivity of the machine and the size changeover speed.

The bags that can be made with this packaging machine have a minimum size of 330 x 400 mm and a maximum size of 580 x 980 mm.

Ask for a quotation, and we will contact you within one business day.

Discover more

Discover more