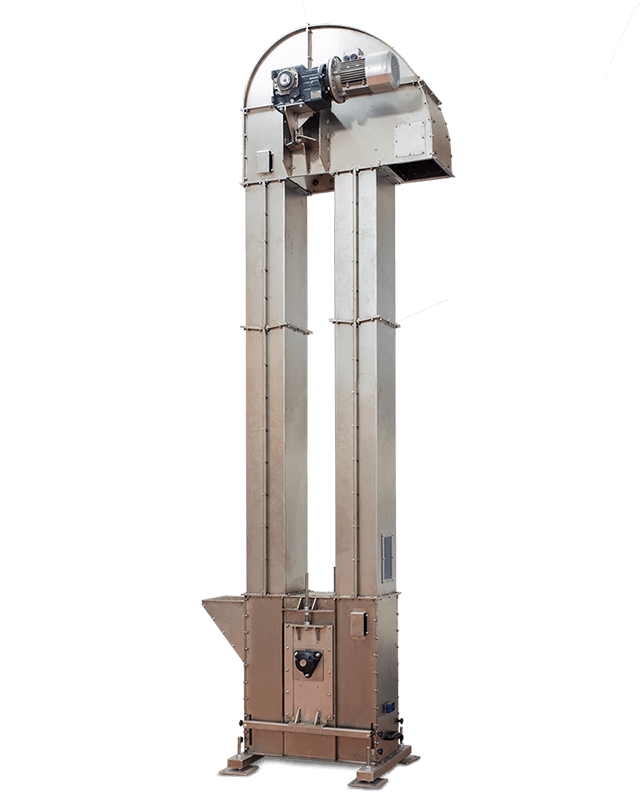

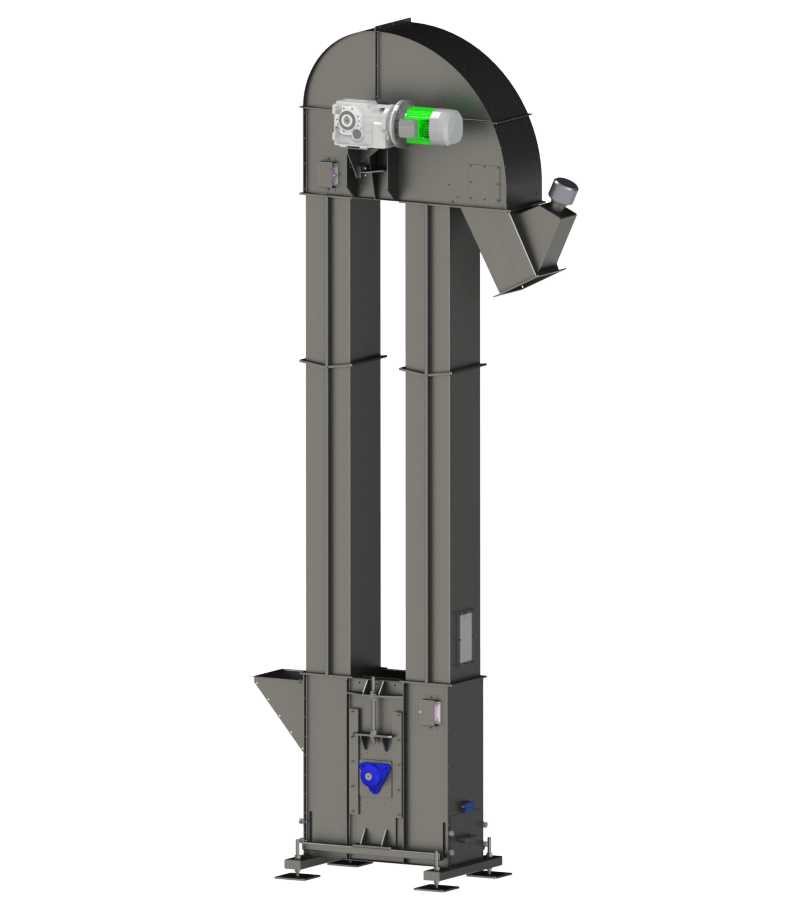

MF TECNO Bucket elevators are engineered for vertical handling and transport, even at great heights, of a vast quantity of bulk products with different granulometry.

Anyway, this is not the ideal solution for conveying fragile products, for which our Pendulum Bucket Elevator is the ideal conveyor.

Our bucket elevators are particularly suitable for transporting salt, sugar, cereals, granuloplastic polymers (TPE), woodchips (small wood shavings from machining waste), pellets of all types (material dried and then compressed into small cylinders), manure and various fertilizers types.

Their versatility makes them suitable for several industries: alimentary, pharmaceutical, chemical, cosmetic, ceramic, metallurgical, and many others.

How a Bucket Elevator works - 3 steps for transporting your product.

1. The product is transported using buckets made of AISI 304 stainless steel, or another material, depending on the customer's preference.

2. The buckets are arranged at regular intervals on a belt driven by a drive pulley, which is held in tension by an idler pulley. The vertical section of the Elevator is made from closed or steel modules and a steel inspection door.

3. The product is collected from the buckets and then transported vertically to the unloading point.

Bucket Elevator: Sturdiness, Speed, Customisation.

Structure material – The material can be chosen between AISI 304 stainless steel and painted steel, according to the client's needs. Both materials offer strength, durability, and maximum hygiene.

Transporting speed – The system's maximum speed is 400 cm/h, however, this parameter can be customized according to the specific needs of the customer.

Customization – The system is highly customizable and offers several options to suit the specifics of the project. You can choose the material of the structure, the loading and unloading points, the conveying capacity in mc/h, and the type of buckets.

Buckets features.

- Available in Aisi304 Stainless Steel, Iron, and Resistant Plastic Material.

- Available in 9 sizes, depending on your product.

- Easy to remove to ensure proper cleaning and maintenance.

- FDA Compliant: material suitable for direct contact with food and foodstuffs.

Bucket Elevator advantages

- Ease of installation: The modular structure allows for quick transport and assembly.

- Low maintenance: The quality of the materials and the design of the access hatches allow easy maintenance.

- Small dimensions: Installation is possible in small spaces and in existing production systems.

Available accessories

Thanks to decades of experience and continuous investment in research and development, we guarantee a high level of performance and numerous accessories including:

- Anti Clogging System (ACS)

- RPM control

- Easy-cleaning system

Below you can find an interesting article about bucket elevator systems.

Also the video of an elevator installed at the Martini Spa company (Longiano, Italy).

Discover more ❯  Request information

Request information  FREE QUOTE

FREE QUOTE  Machinery

Machinery Open Mouth Bagging machines

Open Mouth Bagging machines Vertical packaging machines - VFFS

Vertical packaging machines - VFFS FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information

Discover more

Discover more