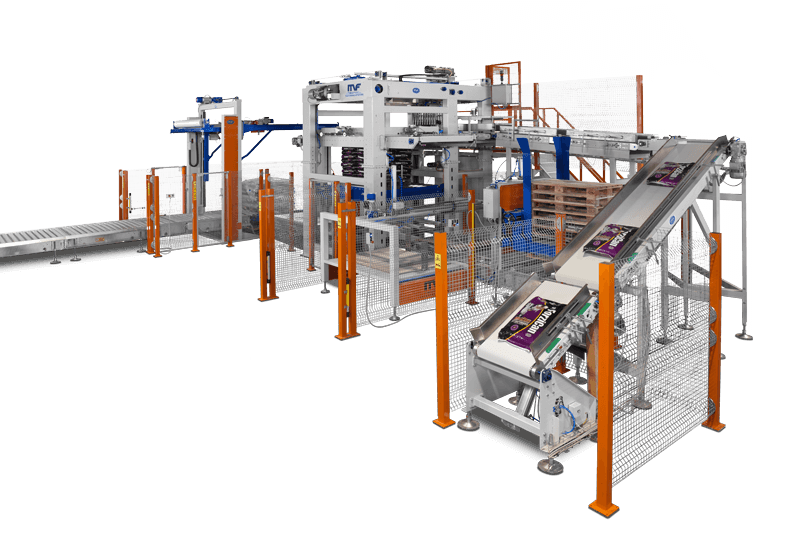

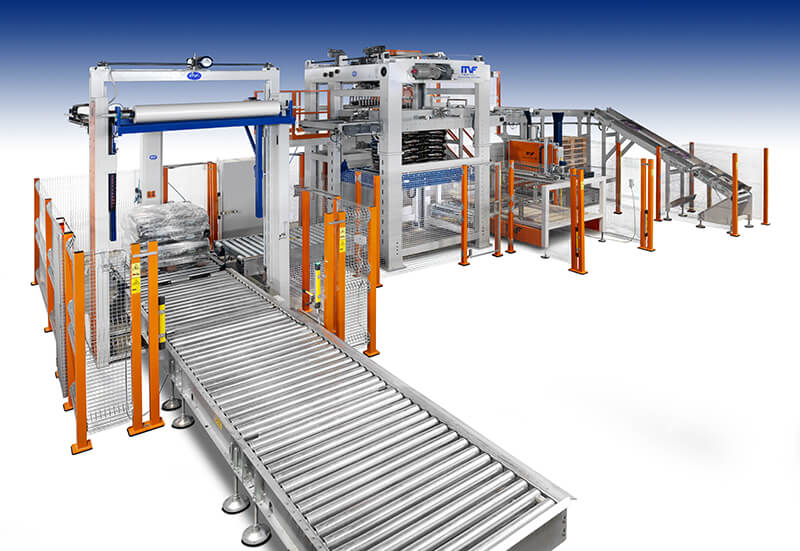

The MF PRC 1000 Cartesian palletizer represents our top-of-the-range solution. This six-column, top-loading robot palletizer guarantees robustness, versatility and production speed. It has a maximum production capacity of 1200 bags/h in single pick-up and about 2000/h in double pick-up.

The quality of the components and layout of this layer palletizer ensure precision and flexibility throughout the entire machining process. Brushless motors move the four axes x y z and r to create an extremely compact and stable pallet. The bags can be partially overlapped, both head-on and sideways, and can be pressed both vertically and horizontally.

Functioning

The conveyor belt, with PVC belt, transports and accumulates the bags coming from the bag packaging line. These, aligned and centred by the bag centring belt, reach the high-low roller conveyor.

Here, a pallettizing gripper, which can be automatically adapted to the width of the sacks, picks them up and deposits them on the layer formation pallet equipped with motorised side compactors. The different layers that make up the pallet can also be separated by an interlayer made from a reel, allowing for more orderly storage.

The z-axis with its adjustable lifting and pressing system combined with the automatic pallet feeder guarantees the automation and efficiency of the entire production process.

The last step is the evacuation of the pallet onto an unloading roller conveyor and the accumulation of the full pallets.

Command and control panel

The operator, via the integrated PLC system with touch screen panel, has complete control of the palletising scheme. He can thus modify a previous programme or create a new one without the intervention of a specialised technician. Modify the speed of the Cartesian robot according to the different operating conditions.

Safety devices

Numerous accident prevention protections are provided including:

- Anchoring to the floor.

- Safety barrier.

- Light barriers, perimeter security guards and access doors.

- Panels complete with electrowelded wire mesh.

- Fall arrest safety device and anti-collision system.

- Ladder and service platform for checks, adjustments and maintenance.

Below there is our complete guide to palletisers.

Discover more ❯  Request information

Request information  Download pdf

Download pdf  FREE QUOTE

FREE QUOTE  Machinery

Machinery Open Mouth Bagging machines

Open Mouth Bagging machines Vertical packaging machines - VFFS

Vertical packaging machines - VFFS FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

FREE QUOTE

Request information

Request information  Download pdf

Download pdf

Discover more

Discover more